Beyond the Mold: The Engine of Excellence in Melamine Manufacturing

2025-12-16

In the world of melamine tableware, the final product – vibrant, durable, and perfectly formed – captures all the attention. But behind every flawless plate, bowl, and cup lies the true hero: advanced, reliable melamine machinery. At DONGXIN MELAMINE, our expertise extends far beyond supplying superior melamine molding compound and melamine dinner set . We are your engineering partner, providing the cutting-edge machinery and technology that transforms high-quality melamine molding compound into best-selling melamine tableware.

Why Your Choice of Melamine Machinery Defines Your Product & Profitability

The right equipment is not just an expense; it's the most critical investment in your production line. It directly determines:

Product Quality & Consistency: Precision in pressure, temperature, and timing ensures uniform thickness, perfect lamination of designs, and a flawless, glossy finish every time.

Production Efficiency & Output: Modern, automated machines significantly increase cycle speed, reduce manual labor, and maximize your daily yield.

Operational Cost & Waste Reduction: Energy-efficient presses and optimized molding processes lower utility costs and minimize material waste, boosting your bottom line.

Versatility & Innovation: The right machine allows you to explore complex shapes, intricate designs, and diverse product lines to stay ahead of market trends.

Our Comprehensive Melamine Machinery Solutions

We bridge the gap between ambition and production. Our offerings are designed for both established manufacturers and new entrants to the industry.

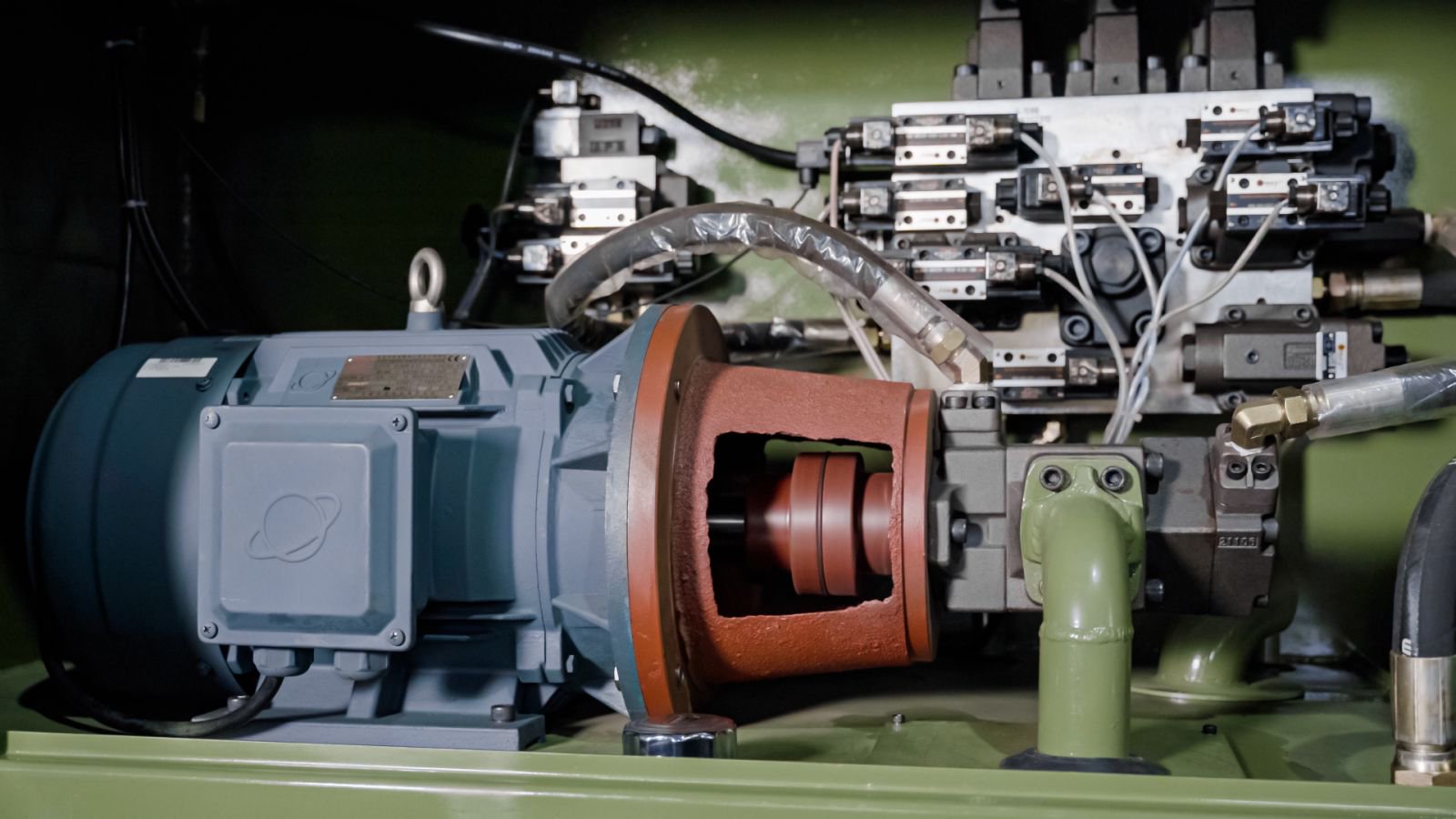

Fully Automatic Hydraulic Presses: The core of any melamine line. We offer a range of tonnage options to suit your production scale, featuring PLC control systems for repeatable precision, energy-saving designs, and robust construction for 24/7 operation.

Auxiliary & Supporting Equipment: A seamless production line requires more than just a press. We provide the complete ecosystem:

Pre-heating Ovens: For uniform powder preparation, leading to better flow and superior product density.

Automatic Powder Dispensers: Ensure accurate, consistent material weight for each mold, critical for quality and cost control.

Grinding & Polishing Machines: For finishing edges and surfaces to a perfect, food-safe smoothness.

De-flashing Machines: Automatically remove excess flash (burrs) for a ready-to-pack finish.

High-Quality Molds (Tooling): The heart of your product's shape. Our in-house or partnered mold-making service delivers durable, precision-engineered steel molds for any design, from classic rounds to custom-shaped pieces.

Technical Integration & One-Stop Service: This is where we truly stand out. Our service is holistic:

(From Formula to Finished Product): We supply the melamine raw material, the decal paper & design, the machinery & molds, and the production know-how.

Installation, Commissioning & Training: Our engineers will guide you from factory floor planning to machine setup and operator training.

Ongoing Technical Support & Spare Parts: We ensure your line runs smoothly for years with reliable after-sales service and genuine spare parts.

Get the latest price? We will reply as soon as possible (within 12 hours)